Shroots is a proprietary brand of VEXCEL Upkram Private Limited – company based in the city or Ranchi in Jharkhand, India.

The company, has an Integrated Agro-Processing Unit based in the city of Ranchi, Jharkhand in India. Designed under the guidance from experts at Spices Board of India, CFTRI, CIMAP and CIAB we have adopted unique and specialised process flows to achieve the highest industry standard .

Industrially, we have procured specialised machine, a major chunk of which are made to order, and devised process specific production lines that meet the best quality standard and yield uniform and high value products.

Our unit has been designed for:

- Machine Dehydration of SPICES

- Machine Dehydration of VEGETABLES

- Machine Dehydration of Jackfruit (high medicinal value)

- Machine Dehydration of Gooseberry (high medicinal value)

- Extraction of high valued Essential Oils

The products mentioned above are only indicative and not exhaustive of the product variety which can be achieved by us.

DEHYDRATED PRODUCTS:

Dehydration removes the moisture from the food so bacteria, yeast and mold cannot grow and spoil the food. As a large share of moisture has been removed, the food becomes smaller and lighter in weight. When the food needs to be used, the water is added back, and the food returns to its original shape.

Both the terms ‘Drying’ and ‘Dehydration’ mean the removal of water. The practice of drying or dehydrating of foodstuffs for preserving them is very old. The former term (drying) is generally used for processing under the influence of non-conventional and uncontrolled energy sources like sun and wind. Dehydration on the other hand, means the process of removal of moisture by the application of artificial heat under controlled conditions of temperature, humidity and air flow.

Drying or dehydration removes biologically active water thus stopping the growth of microorganism. This also results in reduced rate of enzyme activity and chemical reactions.

Though Dehydration is done in such a way that the food value, natural flavor, colour and characteristic cooking quality of the fresh material are retained and only the moisture content is brought down.

We emphasize the term ‘DEHYDRATED’ for our products because unlike the conventionally practiced open sun-drying, we use specialised Hot-Air Dryer Machines to process our products. The chief advantages of our machine dehydrated products are:

- Retention of Aroma, Taste & Medicinal-Properties present as Volatile Oil Content – Our Air Dehydrating Machines are designed to extract only the water content from Agro products whereas sun-drying on the other hand is an unregulated process and results in loss of Volatile Oil and thus it’s Aroma, Taste & medicinal properties

- Microbe/Contaminant Free Product – Absence of micro-organisms growths and contaminations like Poly-Cyclic Aromatic Hydrocarbons (PAH), Salmonella, Aflatoxin etc. is another reason why our products are highly valuable, clean, pure and unique when compared to products dried using alternate and conventional methods, where the adopted process may assist in growth of life threatening microbes & harmful contaminations.

- Heavy Metals – Presence of Heavy Metals in the form of pollution in the atmosphere, no matter which country/state/location, are a common occurring in today’s times and to dry a product which has been largely been processed in these conditions will result in the contamination of the product which is not safe for consumption. Our Hot Air Dryers use filtered air to dry the products avoiding in chance of such an occurring.

- Rehydration & longer shelf life – Dehydrated food can be reconstituted. Once reconstituted, these products are treated as fresh, to reconstitute just add water and soak until the desired volume is restored. Hence, these products can thus be used as required either in their Dehydrated, Powdered or retainable fresh form. As the excess water has been removed, the enzymatic process and further aging of the products slows down, thereby elongating their shelf life.

- Economic Viability – Our products are economically more viable as-well, one may compare the price of our product to a Sun Dried crop which have far lesser flavour, taste and medicinal benefits. Hence for every Kilogram of Sun-dried product currently being used – a lesser quantity of our dehydrated products may be used to achieve the same flavour, taste and/or medicinal benefits. Effectively 1 gram of our Dehydrated Product equals to roughly 15 grams of a freshly harvested crop.

In order to optimise packaging keeping in mind the involved Freight Costs, we have developed specialised packaging methods to reduce bulk storage space and maximise space usability, whilst keeping the product quality to the highest and safest standards.

ESSENTIAL OILS:

We have set-up a highly specialised Essential Oil extracting line, which is designed to extract oils from the lowest yielding crops like Ginger as well. Essential Oils from fresh agro produce are extracted by the process of Steam-Distillation by us. We are currently supply Essential Oils from Lemon Grass, Ginger, Turmeric, Eucalyptus, Palma Rosa, Peppermint, Lemon Grass & Spearmint.

CONCENTRATES FROM PULPS:

Pulp concentrates a merely pastes of a pulp bearing product, from which all the excess water content has been removed, which increases it’s shelf life and yields a product which packs more pulp and minimal water. The pulp concentrate manufacturing line has been designed to yield a concentrated product of upto 65 Brix and having a unique flowability in it which is not found in other similar products available in the market.

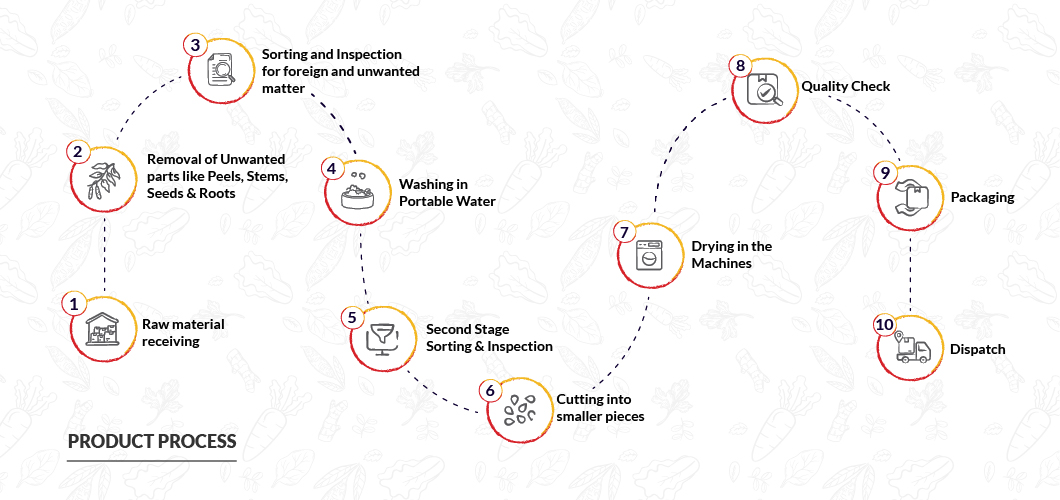

A brief of our process flow is described below for your reference. The processes are largely divided in product categories.